CATEGORIES

FEATURED PRODUCTS

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

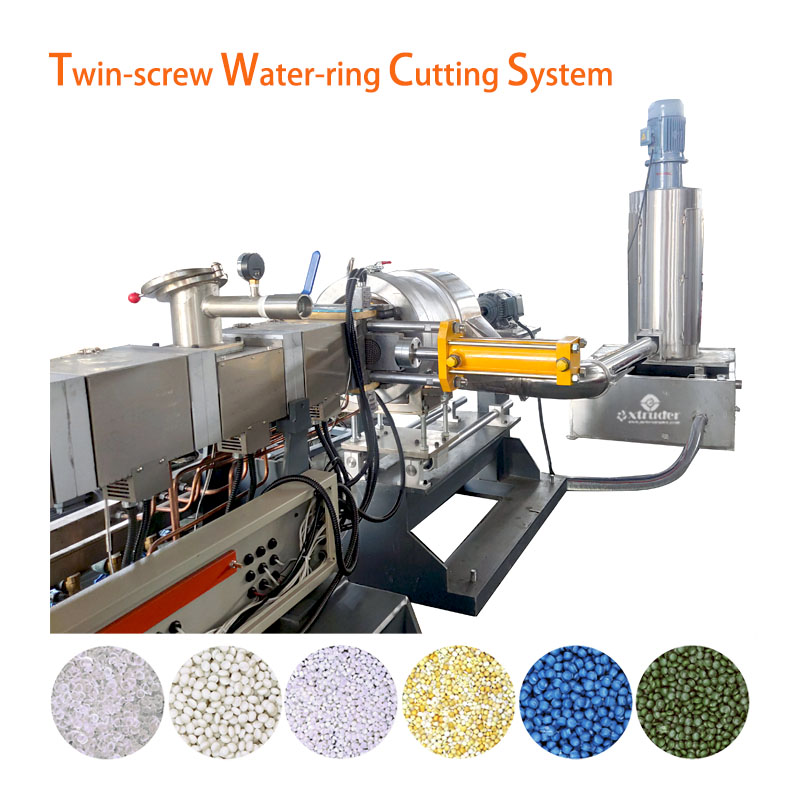

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

SHORT DESCRIPTION:

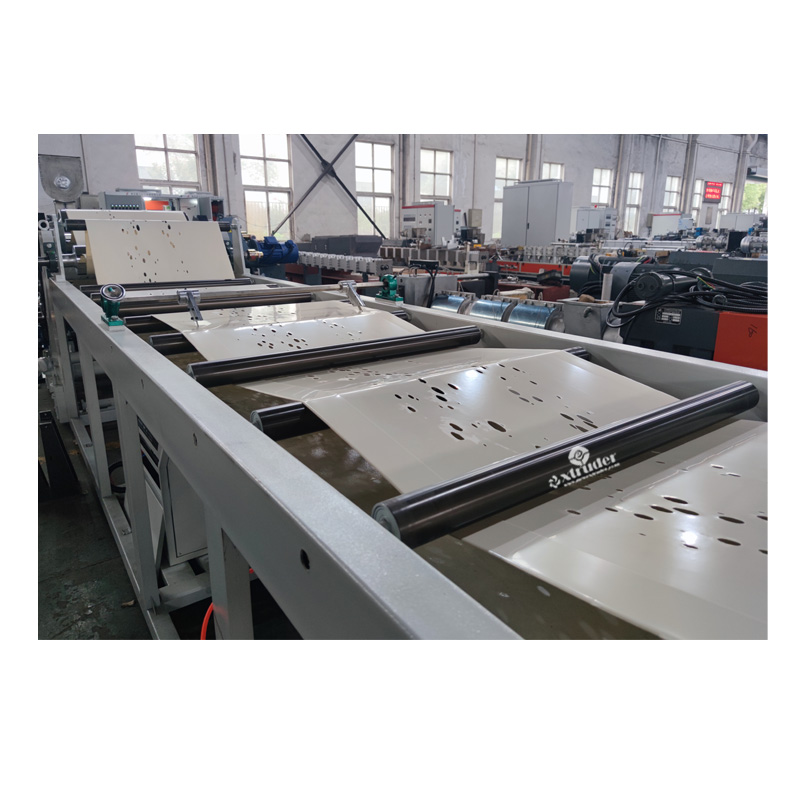

These Plastic Sheets Extruder Machine Lines could make a different kinds of carriers, like PE,PP,PVC,PBS,PLA Etc. If you need to set up a special degradable plastic sheets machine line, our newly designed Bio-degradable plastic sheets extrusion machine line is your good choice!

- Product Detail

- Our machine can process the following materials:

- Product Tags

Plastic sheets applications:

These Plastic Sheets Extruder Machine Lines could make a different kinds of carriers, like PE,PP,PVC,PBS,PLA Etc. If you need to set up a special degradable plastic sheets machine line, our newly designed Bio-degradable plastic sheets extrusion machine line is your good choice!

|

|

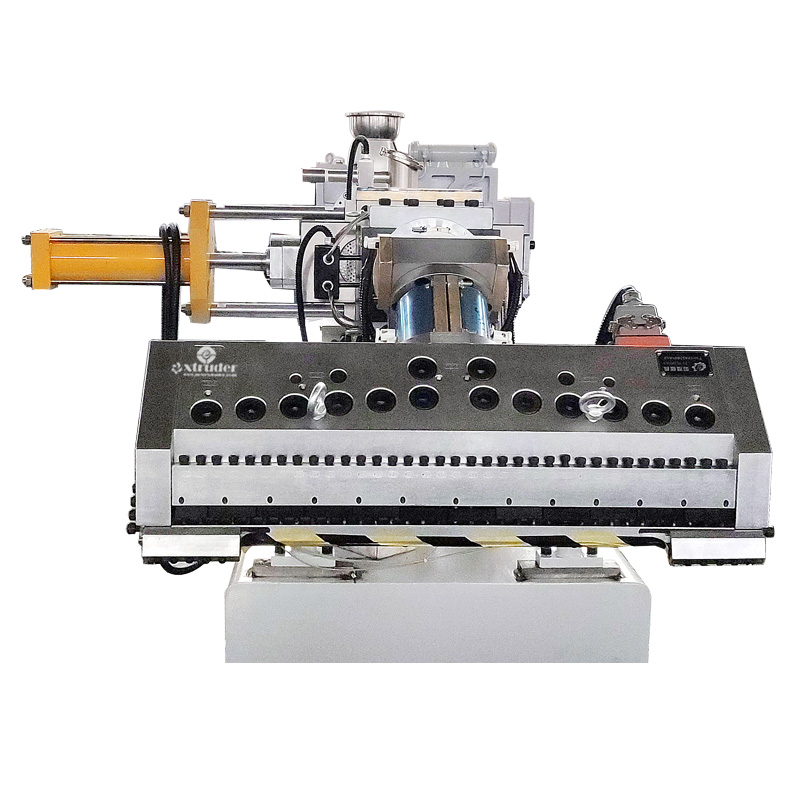

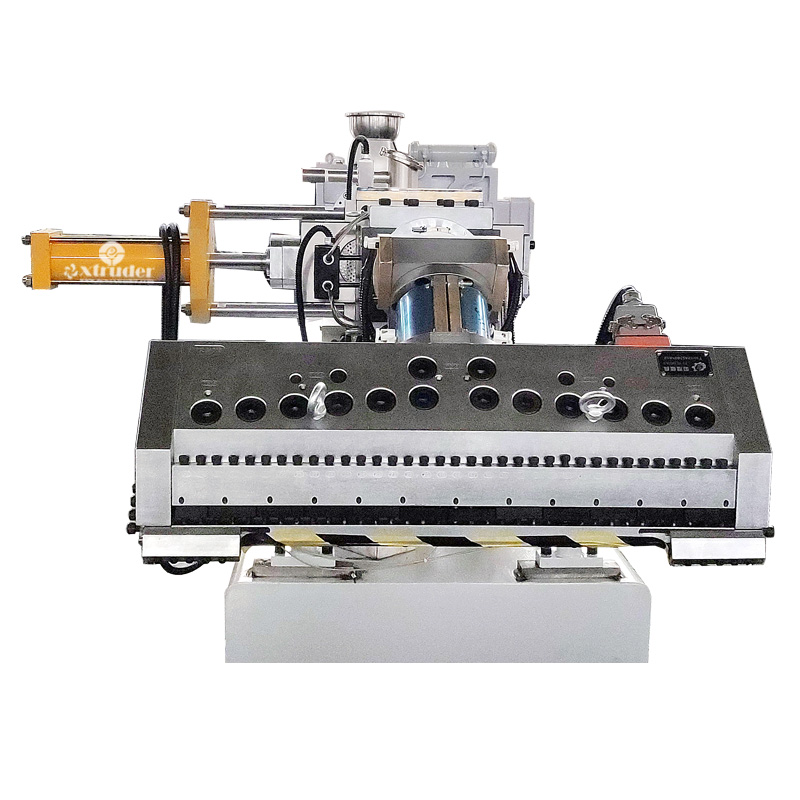

Good quality T-shape coat hanging mold, the width could be from 300-1800mm according to the relative sheets extruder machine output capacity the clients needed.

|

|

The machine line is equipped ABB brand inverter, Siemens Beide or Wannan brand AC motor, and also set a melt pump for the extrusion machine line which could be keeping the material requested pressure and let the extrusion machine continues extruding and let the melt material go ahead smoothly.

|

|

The machine line is equipped ABB brand inverter, Siemens Beide or Wannan brand AC motor, and also set a melt pump for the extrusion machine line which could be keeping the material requested pressure and let the extrusion machine continues extruding and let the melt material go ahead smoothly.

Three roller calender is extruding sheets for clients’ requested thickness.

|

|

Sheets collotor ( wrinder for sheets rolling).

The machine line is equipped ABB brand inverter, Siemens Beide or Wannan brand AC motor, and also set a melt pump for the extrusion machine line which could be keeping the material requested pressure and let the extrusion machine continues extruding and let the melt material go ahead smoothly.

|

|

sheets’ edge cutting for width size requested.

|

|

|

|

About Us

We do things a bit differently, and that’s the way we like it!

Kosin New Rubber & Plastic Extruder Machinery Co., Ltd. is a specialized manufacturer of professional designing and making co-rotating parallel twin-screw extruders, three screws plastic extruder, granule equipment and spare parts. Our factory manufactures complete set of plastic extrusion equipment, and provides related crafts, technical development, and advisory service. Our company has a lot of domestic current seniors and specialized technical persons in co-rotating parallel twin-screw extruder domain.

Our main products are fall into reinforce and modification plastic business:

1) Co-rotating parallel method Twin screw plastic extrusion machine:

Various kind of carriers, like to say, PE/PP/ABS/PA/PET/PVC/TPU/TPR & Etc.;

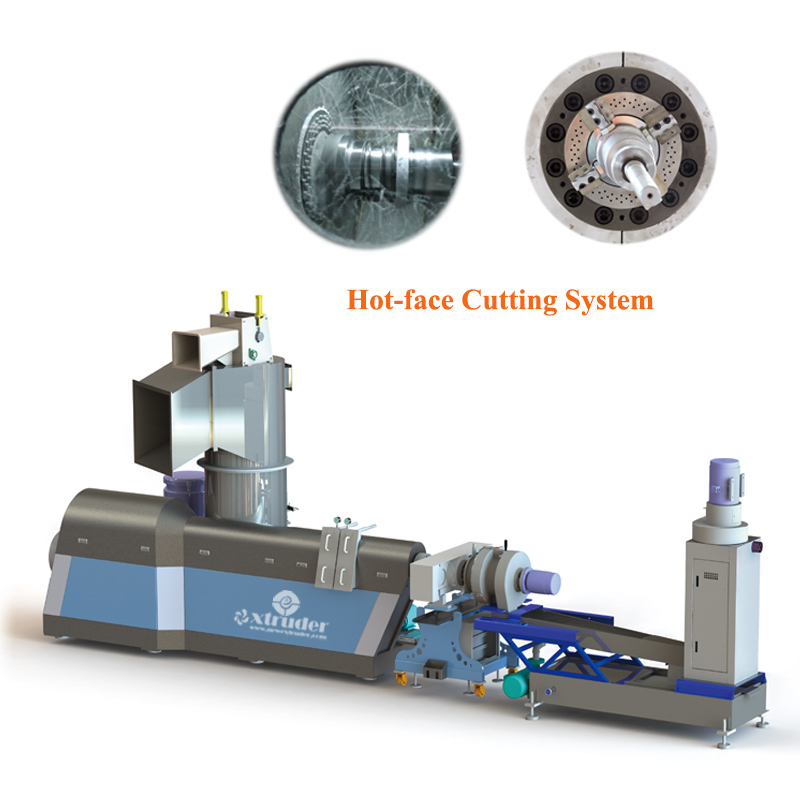

Various cutting method, like to say:

- *. Strand bathing water cooled pelletizing system

- *. Water ring cooled strand hot-face cutting system

- *. Air cooled strand hot-face cutting system

- *. Air cooled strand belt convoying pelletizing system;

- *. Water flushing and cutting in the water cutting system;

- *. Under water pelletizing system;

- *. And other special cutting system;

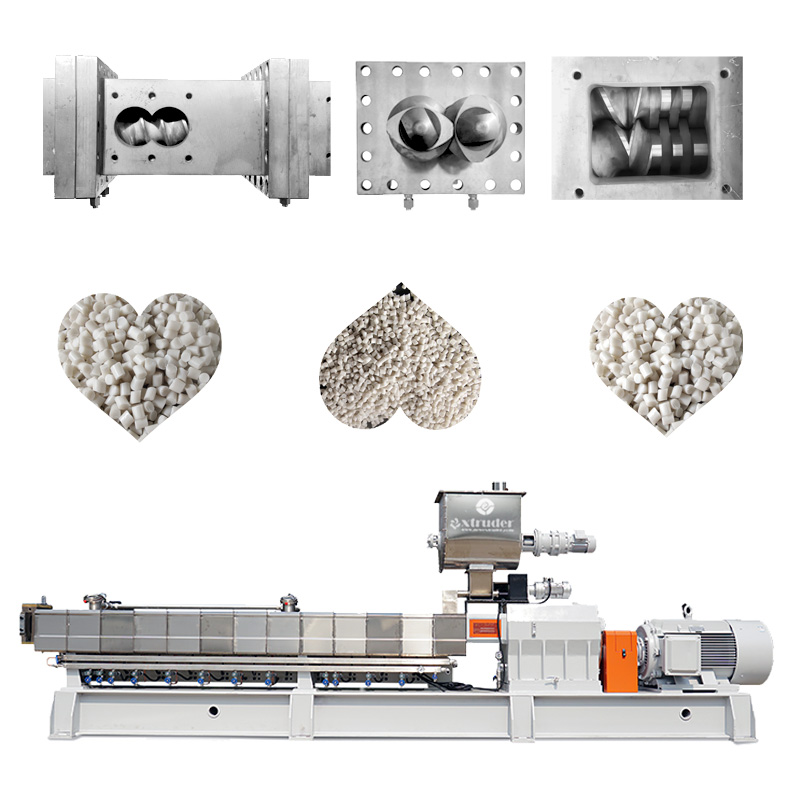

2) Twin screw plastic sheet making line; like to say PE/PP/PC/PET/PVC

3) Twin Screw Bio mass degradable plastic extruder;Degradable plastic pure or modification for granules making, like to say PBAT, PHA & Etc.;Degradable plastic pure raw material or modification material extrude into Sheets, like PLA, PBS & Etc.;

4) Three shafts(screws) plastic extruder for filler and master batch for large output capacity requirements.

5) Recycling plastic granulating machines: like PET bottle chips, or PET waste films’ pieces are redo granulate into the particles.

6) Professional machine and equipment for PCB business field.You’re welcome to visit our website and our factory, and we hope we could have a closed to create mutual resplendence tomorrow.

Our mission is:CUSTOMER COMES FIRST!

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |

Previous: PCB SAWING MACHINE