CATEGORIES

FEATURED PRODUCTS

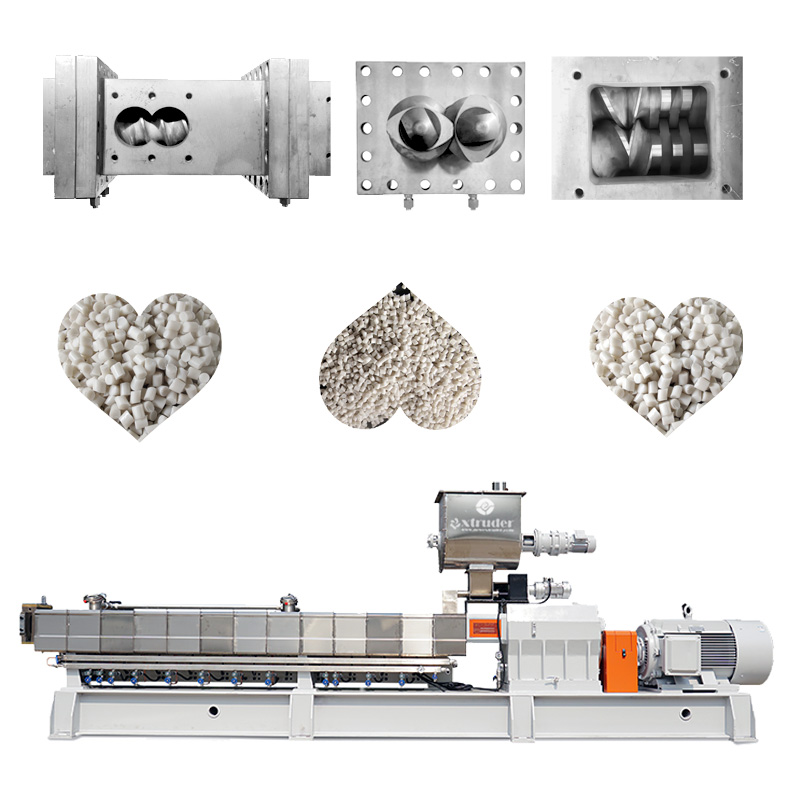

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

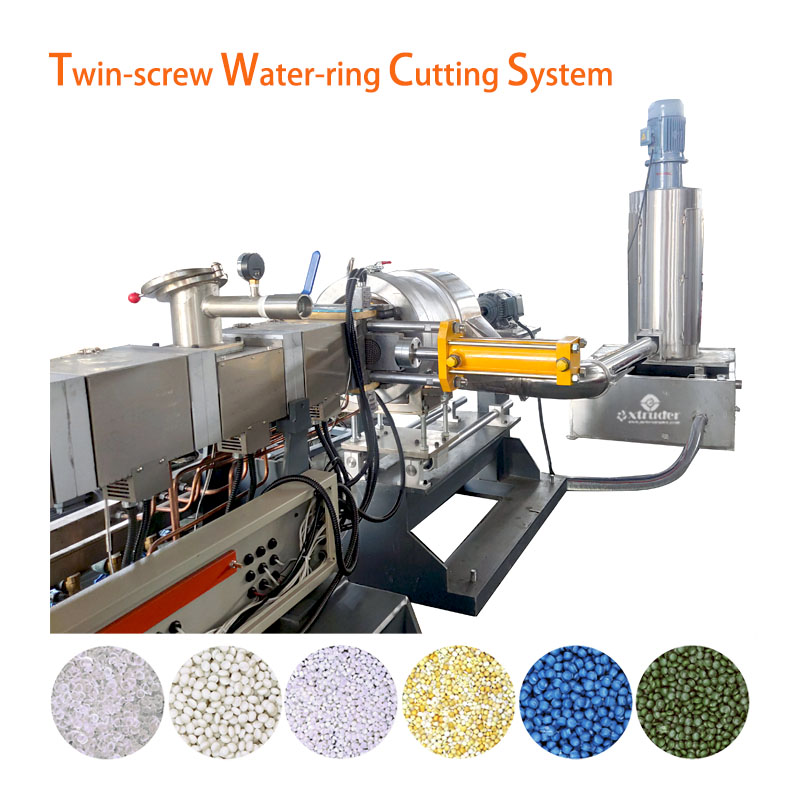

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

PVC cable extruder Two stage plastic polymer extruder high concentration filler and color masterbatch machine

SHORT DESCRIPTION:

PVC cable extruder Two-stage plastic polymer extruder high concentration filler and color masterbatch machine

- Product Detail

- Our machine can process the following materials:

- Product Tags

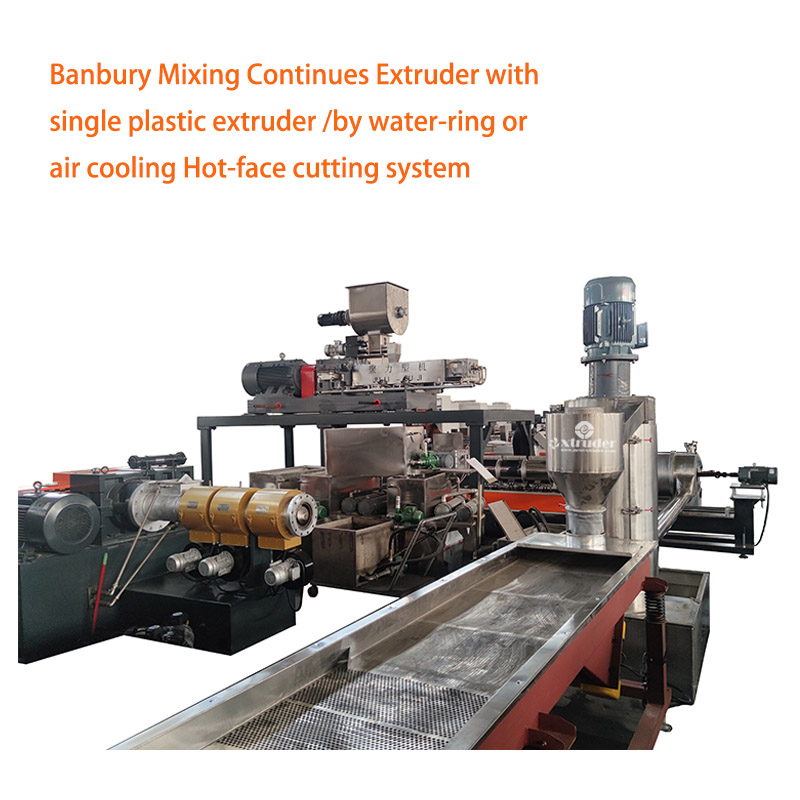

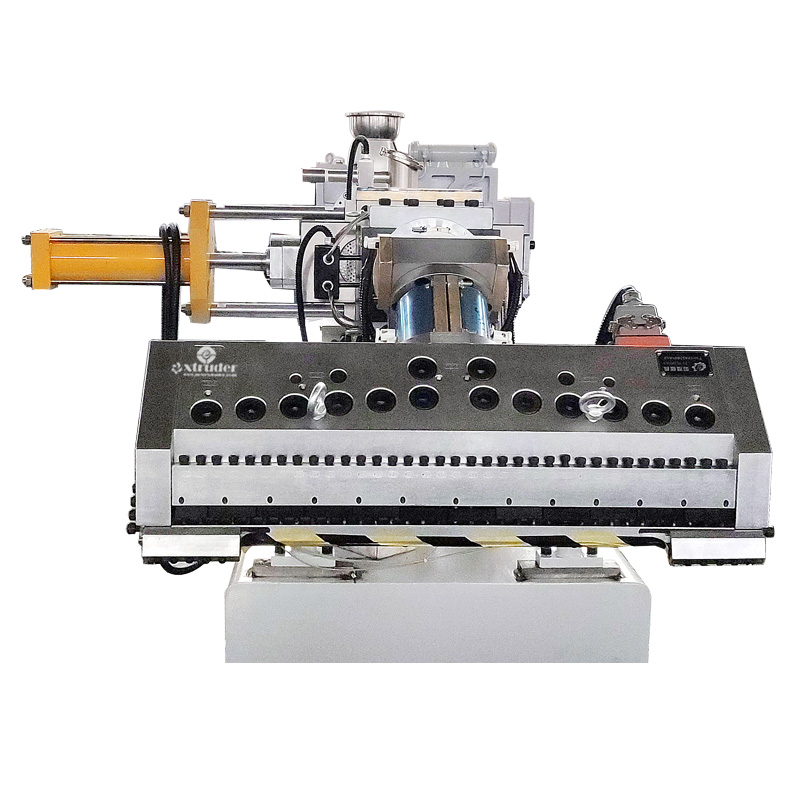

Air cooling hot-face cutting system extruder

PVC cable extruder Two-stage plastic polymer extruder high concentration filler and color masterbatch machine

HS CODE: 8477.2010

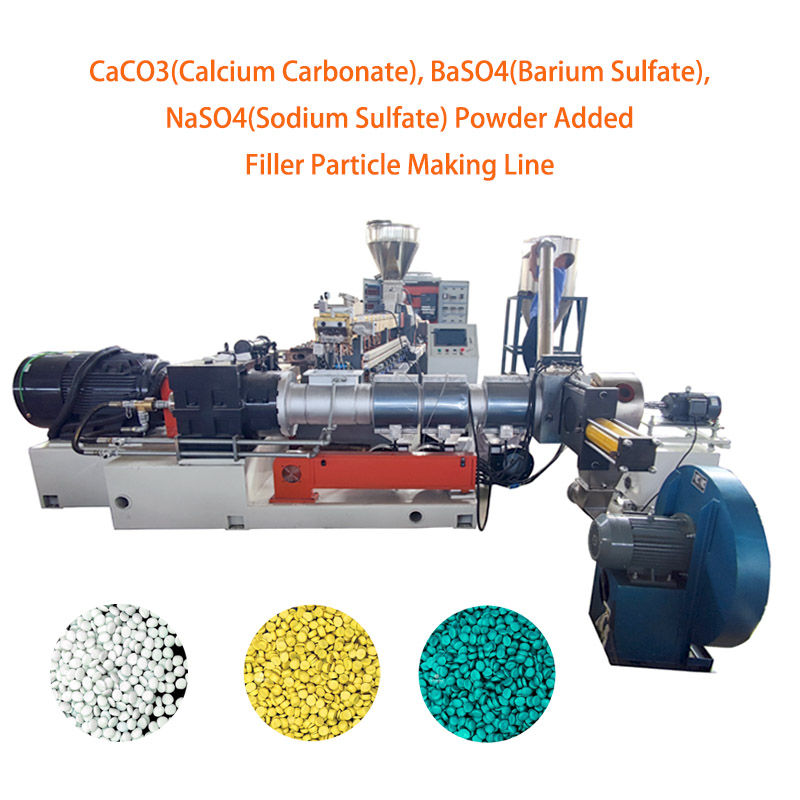

Application(Purpose): This PVC cable extruder machine is an extrusion group used for: heat sensitive material and high percentage added filler, CaCo3 (Calcium Carbonate) powder, BaSo4(Barium Sulfate) powder, Talcum powder, black carbon Etc.

Water cold strands pelletizing system

More Details about the air-cooling hot-face cutting system twin screw extruder:

|

|

PVC classification

PVC insulated cable material

PVC sheathed cable material

Flame retardant PVC insulated cable material

Flame retardant PVC sheathed cable material

PVC elastomer cable material

PVC outdoor overhead insulated cable

Other classification

Air–cooling hot-face cutting system twin screw plastic extruder

PVC cable material is made of polyvinyl chloride as the base resin, adding stabilizer, dioctyl phthalate, diisodecyl phthalate, dioctyl terephthalate, trioctyl phthalate and other plasticizer as well as calcium carbonate and other inorganic fillers, additives and lubricants and other additives, after mixing and kneading extrusion and prepared particles.

PVC cable material processing technology

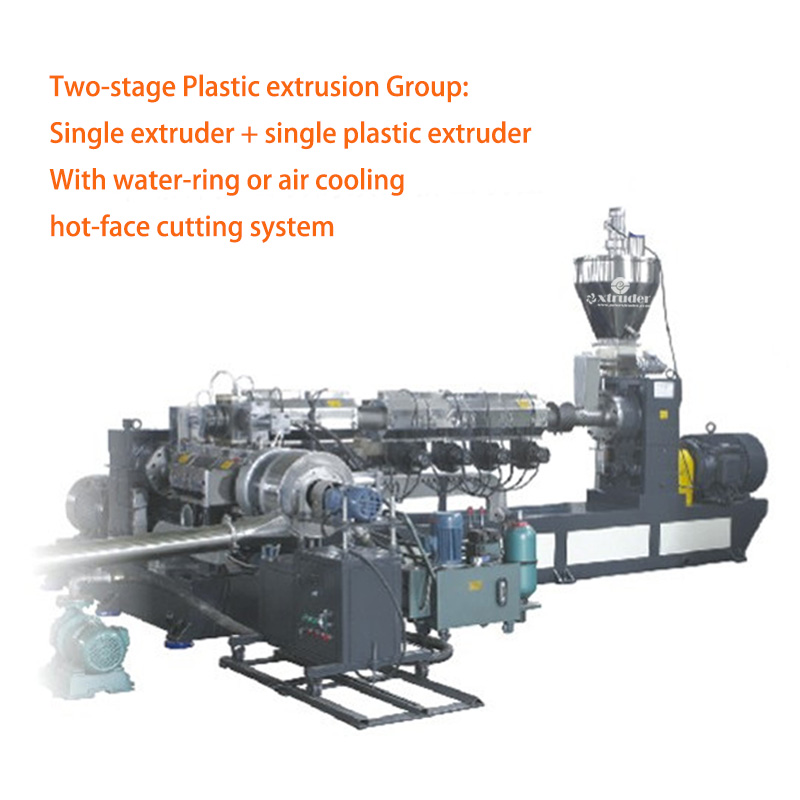

The length length ratio (L/D) of SHJ-65B twin screw is 32-40;

D-150 single screw length-diameter ratio(L/D) required at 9-11;

single screw axis has a water running channel in the middle; –>Hydraulic screen change –> Extrusion die-head designed by push and pull one; (Do PVC elastomer with this nose is there will be a phenomenon of clay) –>The air-cold hot-face cutting system –> The first section of the cyclone separator –>1#Vibrating sieve–>The second section of the cyclone separator –> 2#Vibrating sieve–>The third section of the cyclone separator –> extended vibrating screen –>Silo(if you need pack the bags then set an Automatic packaging machine(finish);

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |