NEWS

Twin screw plastic extruder troubleshooting Temperature set is a very important thing

Twin screw plastic extruder troubleshooting Temperature set is a very important thing

A customer called me today to say that after only a few days of using his equipment: twin screw plastic extruder, the gearbox output shafts spindle and the extruder shafts were broken, and to complain that the quality of our equipment was so poor……. bala bala…….. I asked the customer to calm down, to explain the accident to me clearly, like to say, what raw materials and carriers are processed, what particles are produced, what is the production process, asked him to describe the accident by more detailed information .

The customer was furious, saying we have been producing this product for many years, everything is right except the poor machine! And stressed again and again It‘s no problem with their formula and technical process.

In the spirit of being responsible for the equipment and the customer always right, we apologized to the customer repeatedly for the trouble caused by our twin screw plastic extruder. After that, I asked the customer to disassemble the broken parts and package the transmission box and the whole set of screws segments, shafts of the plastic extruder and send them back to me as early as possible, so that we can fix the problem and the customer could recover the production again soon.

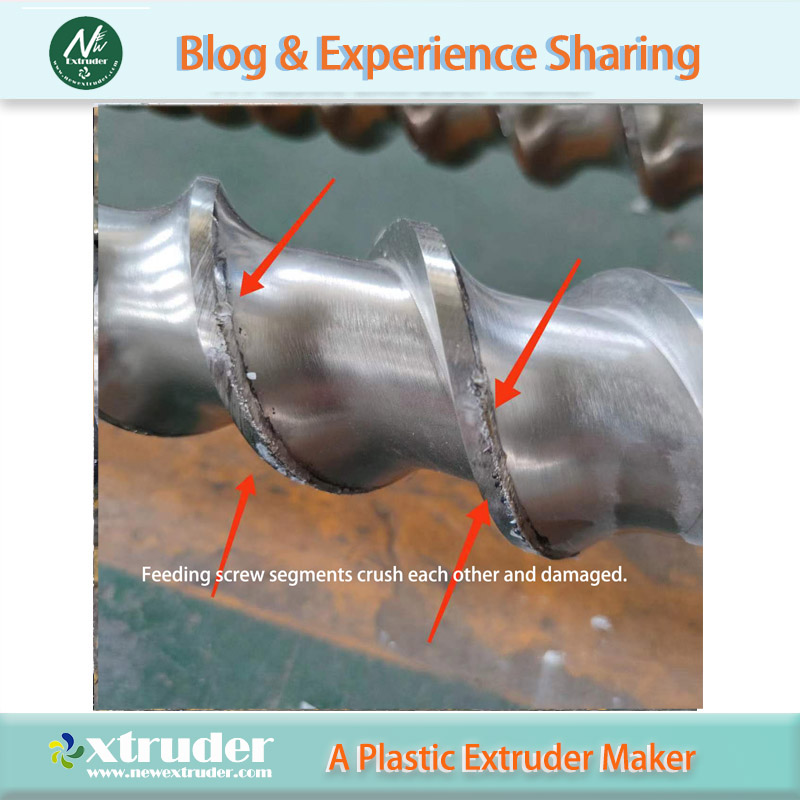

The next day, the damaged parts package has reached to my hand. And I was shocked when I opened the package. The two pieces of output shaft of gearbox fractured and the fracture surface is uniform and neat, in the meantime, the spline part of the shafts has been distorted.

These parts must be faced a suddenly strong power forced to pull the shaft in two parts and the broken surface almost flat and level, another reason is that a very hard foreign object enters the feeding barrel and broken the screw segments and broken screw segments destroyed the shafts. …………Suddenly an idea flashed through my mind: maybe this production accident caused by the operator himself: maybe the processing temperature did reach into the set one, and the operator start the machine line running…………

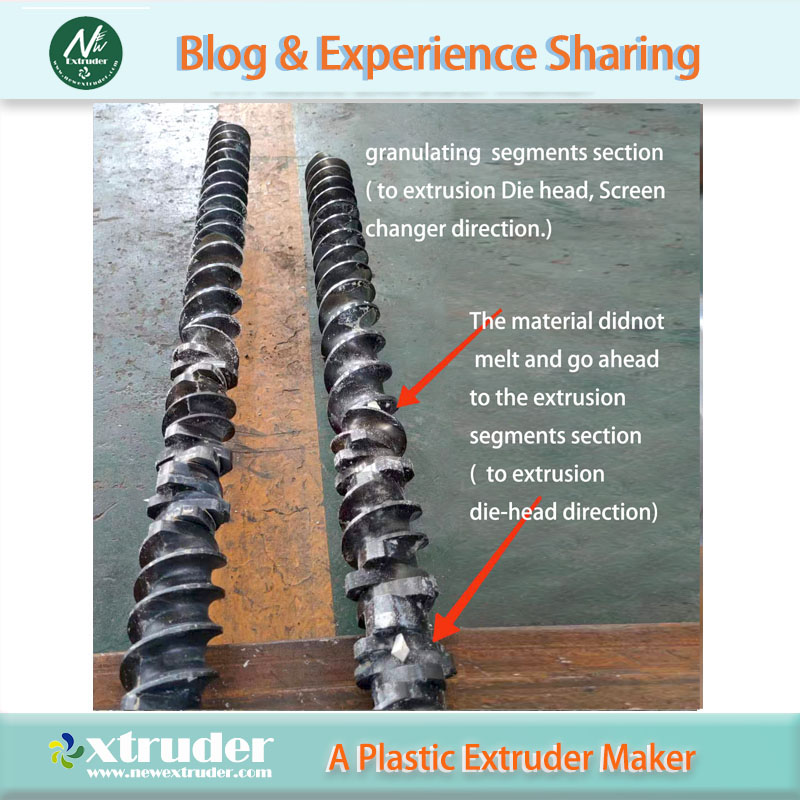

With a sense of foreboding in my mind, I quickly opened the anti-collision package of the plastic extrusion screw. At the position of the extrusion barrel section of the screw segments, a pile of didn’t melt materials fell to the ground one after another. What does this mean the material has not melted at the extrusion granulation stage by the twin screw plastic extruder die head? Apparently, the customer’s claim that he had professional knowledge in the formula and technical processing experience in their product making was completely different, either he was hiding some important link or really didn’t understand how to use a twin screw plastic extruder.

Call the customer euphemistically and tell him whether an operator had a mistake to operate the twin screw plastic extruder by a high speed running when the material temperature did not reach the set temperature? also, I told him we saw the phenomenon and find the reason of the parts damaged. The customer no longer defend this matter.

The following step it is easy to deal with, because the plastic extruder is in the warranty period, but it’s a man-made damaged accident, the client only need to pay the cost of replacement parts , well, I consider the customer benefit, and they are the domestic market customer, the freight of damaged parts round-trip is not very expensive and there is no need to do other clearance things and there is no other extra charges popup, so we decided all the transportation charges will be born from our side.

on other hands, since the customers trust us to buy plastic extruder machine lines from our side, we are also responsible for every customer, and would treat each plastic extrusion machine line like our children.

At the same time, we asked the customers repeatedly stressed that professional equipment should pointed to a trained operator to run the plastic extruder machine. Also, asked our after-sale department to do pre-job training for clients’ workers is a very important thing, must be train the operators enough after installation and debugging the machine lines.

This problem in the company as a typical accident to remind everyone, also to alarm every employee: safe production! safe operation!

The customer is satisfied with our service, and told us they will have the first consideration to purchase the plastic extruder machine from us next time because of our professional knowledge, quick response and have good after-sales service in this business field.

Please pay attention to my blog and the expertise will continue to update.

Thanks & have a nice day!

if you have any question, you can friend me by WhatsApp or Wechat for discussion.

forward from www.extruderonline.com-blog