CATEGORIES

FEATURED PRODUCTS

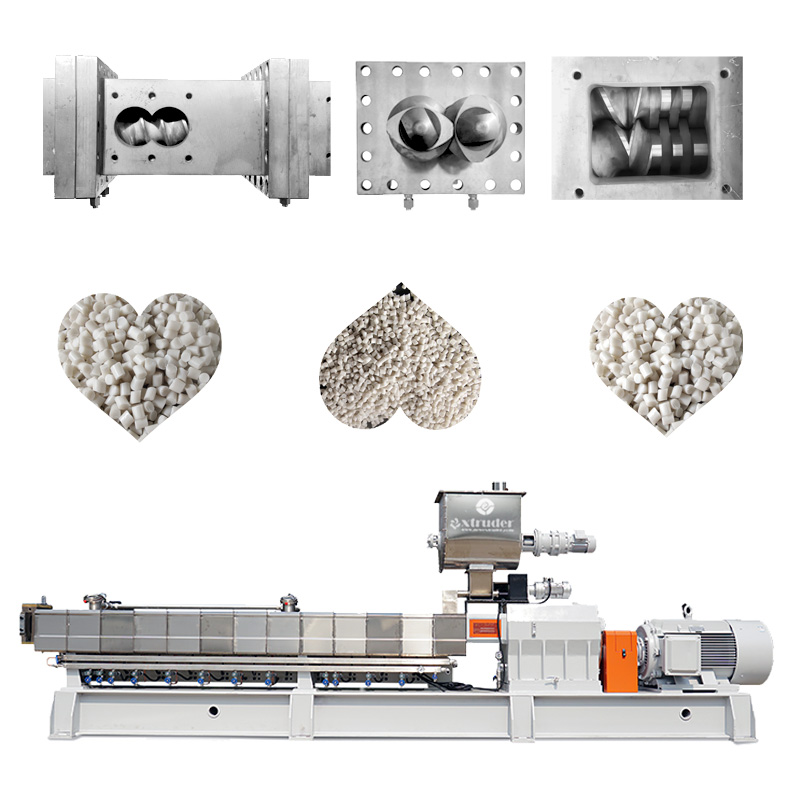

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

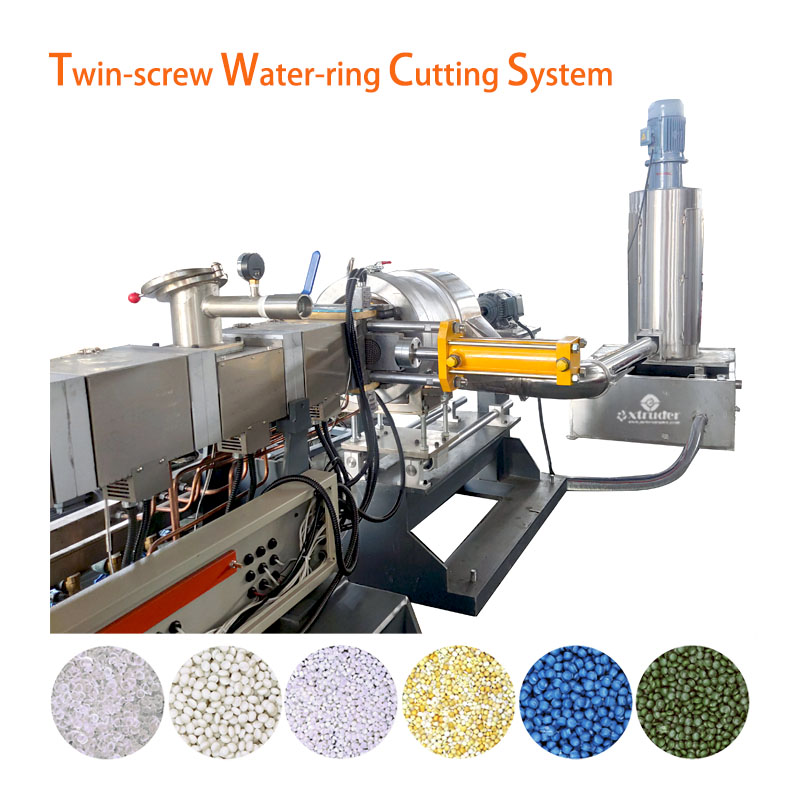

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

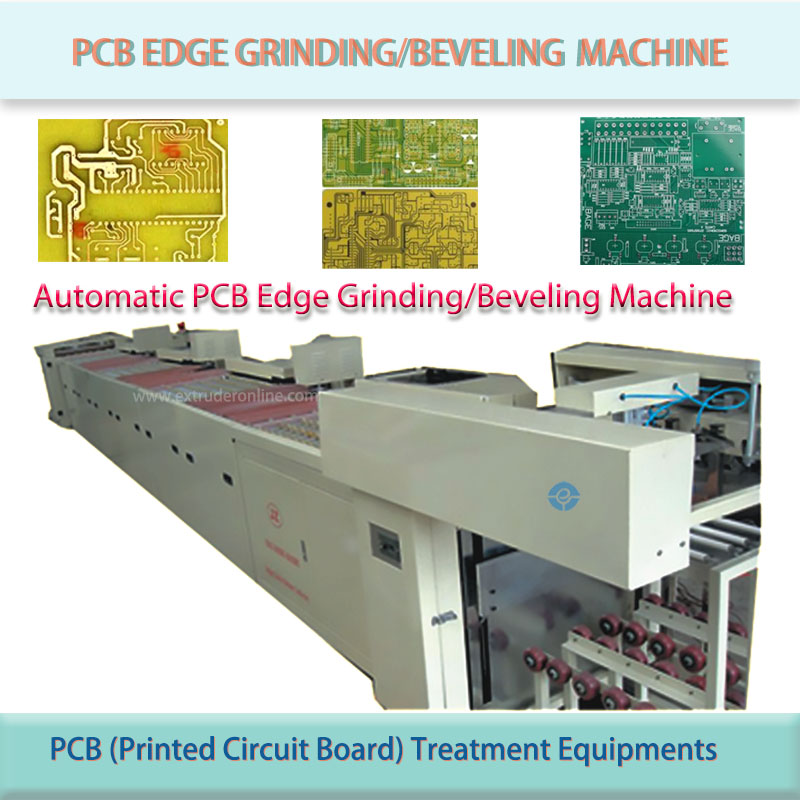

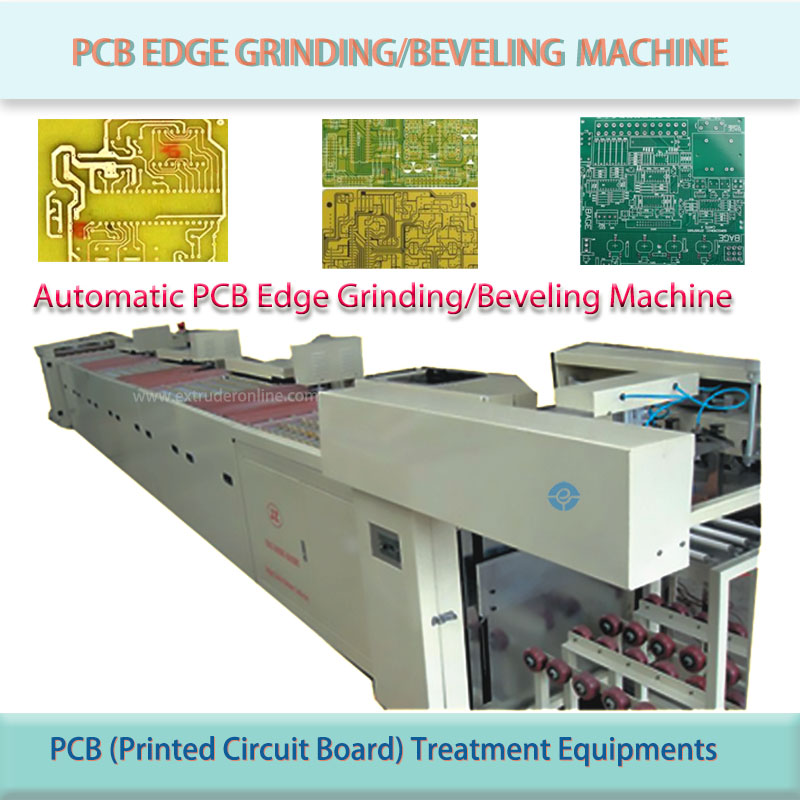

PCB Edge Grinding Beveling Machine

SHORT DESCRIPTION:

PCB Edge Grinding Beveling Machine for printed circuit board making factory JZ Automatic Edge Grinding (Beveling) Machine Purpose: PCB Edges’ Grinding /Beveling

- Product Detail

- Our machine can process the following materials:

- Product Tags

PCB Edge Grinding Beveling Machine for printed circuit board making factory

This machine is for the PCB factory to use to make the PCB four edges.

HS CODE: 8465920000 OR 8479899990

Purpose: PCB’S Edge Grinding /Beveling, to flat the four edges.

|

|

Advantage of PCB Edge Grinding Beveling Machine

Automatic Unreeling and Collecting PCB(Printed Circuit Board).

Adopting single side grinding (beveling), avoid grinding the PCB shape into Rhombus (diamond shape).

Equipped special devices for avoiding two workpieces come in or come out at the same time.

Technical Data for PCB Edge Grinding Beveling Machine

Power: AC220V/380V,50Hz/60Hz, 3Phase,

Machine Controlling: AC220V, single phase, 50Hz,

Total installation power: around 4KW;

Air source: 6-8Kg/cm2, total air consumption:1000L/Min.

Dust collect plant: Max. static air pressure: 1000mmAQ,

Blast Capacity: 25M3/Min.

Suggesting pipe for dust collecting: around 76mm

PCB Thickness: Min. 0.4mm, Max.: 3.2mm

PCB size: Min. 200mm*200mm, Max.: 610*610mm

Transferring speed: 10M/ Min.

Effective length for working: 900± 50mm

Output capacity: 7-8PCS/Min. (10PCS or over if by only grinding edge operative mode.)

TAGS : PCB EDGE BEVELING MACHINE PCB EDGE GRINDING MACHINE CCL GRINDING MACHINE CCL BEVELING MACHINE PCB Equipment Manufacturer PCB EQUIPMENT

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |