CATEGORIES

FEATURED PRODUCTS

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

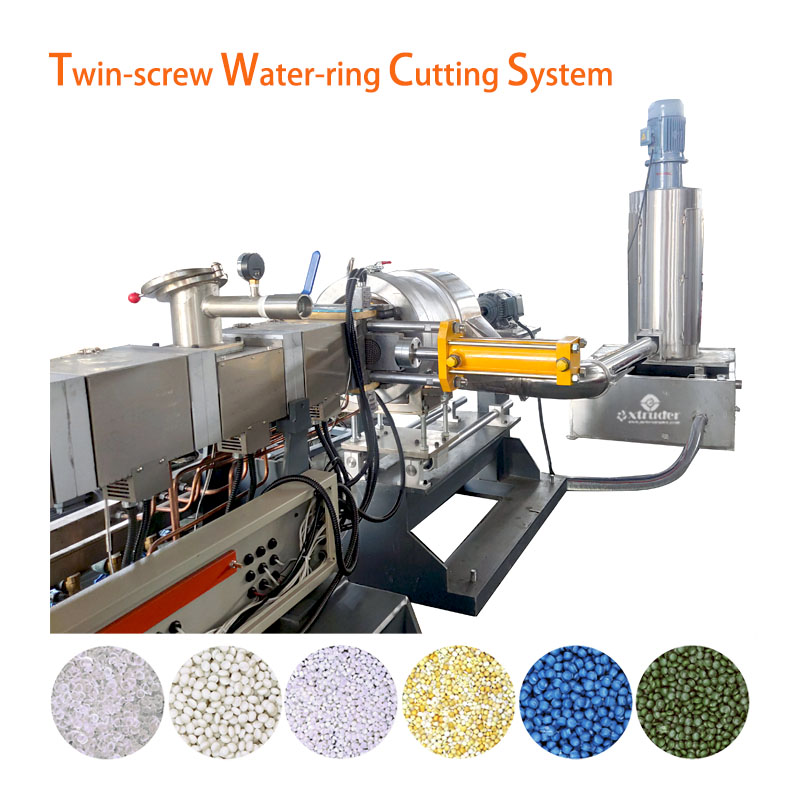

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

Air Cold Hot-face Cutting System Twin-screw Extruder Machine PE PP PVC add Starch Calcium Carbonate Powder Particles

SHORT DESCRIPTION:

PVC cable extruder Two-stage plastic polymer extruder high concentration filler and color masterbatch machine

- Product Detail

- Our machine can process the following materials:

- Product Tags

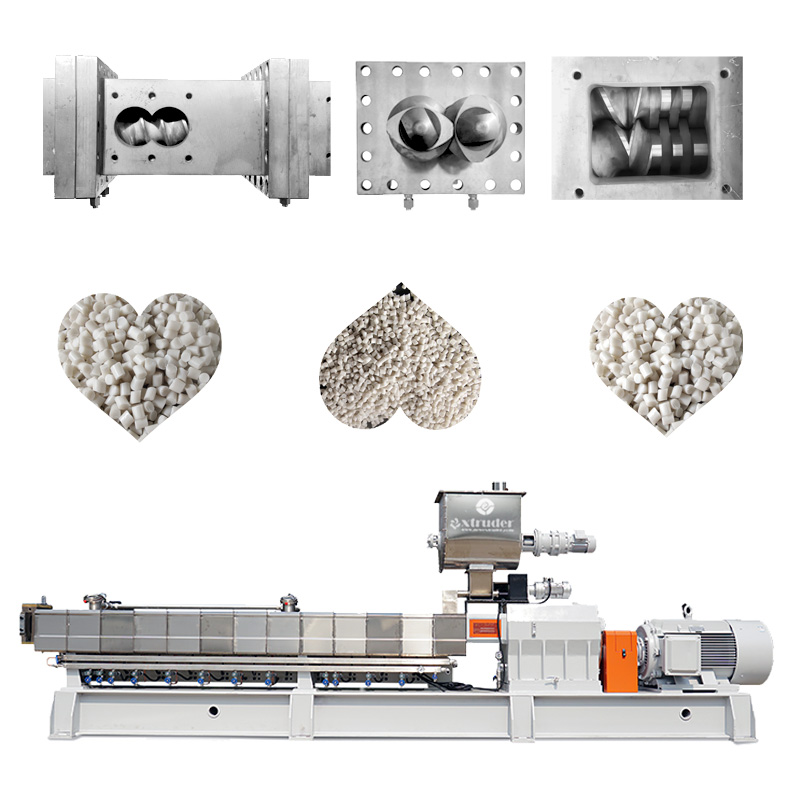

Air–cooling hot-face cutting system twin screw plastic extruder

PVC cable material is made of polyvinyl chloride as the base resin, adding stabilizer, dioctyl phthalate, diisodecyl phthalate, dioctyl terephthalate, trioctyl phthalate and other plasticizer as well as calcium carbonate and other inorganic fillers, additives and lubricants and other additives, after mixing and kneading extrusion and prepared particles.

Classification of PVC cable

PVC insulated cable material

PVC sheathed cable material flame retardant

PVC insulated cable material

PVC elastomer cable material

PVC outdoor overhead insulated cable

Others

|

|

About PVC cable extruder/ Two stages extrusion group machine

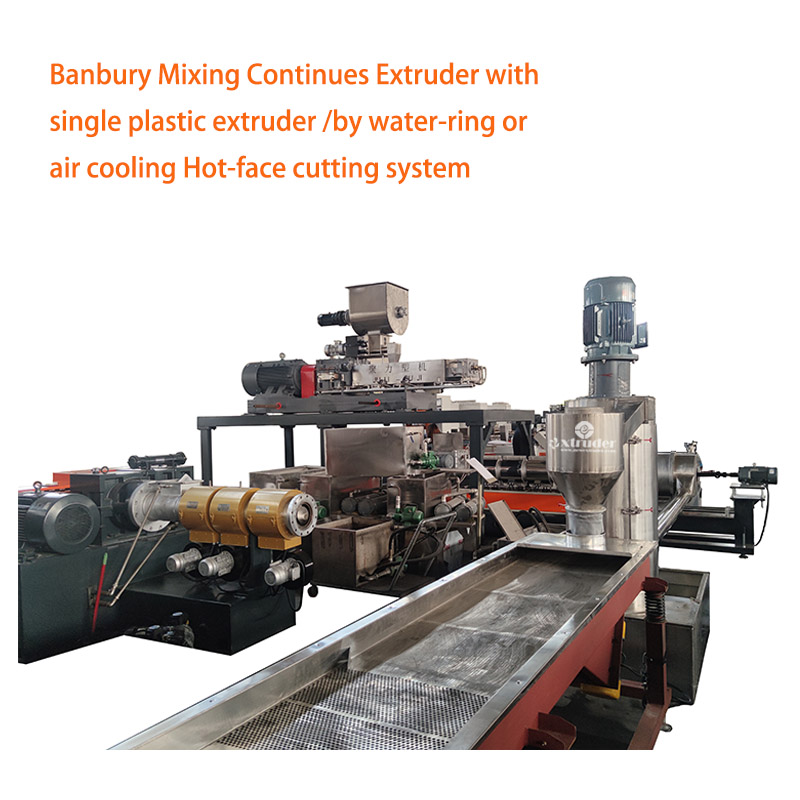

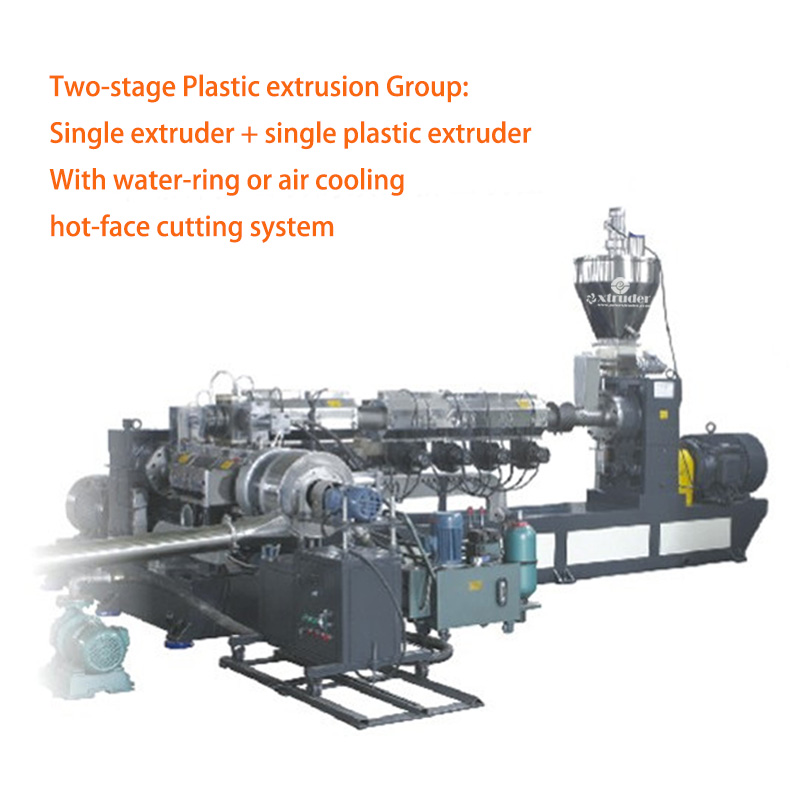

PVC cable material pelletizer uses a double-stage pelletizer. The first stage is GLS type high-speed same direction twin screw extruder, the second stage is GLD series single screw extruder, which constitutes a double-stage compound unit, basic structure form: characteristics: double screw high speed, strong mixing with single screw low speed, low temperature, weak shear characteristics combined, make use of strengths and avoid weaknesses, is today’s heat sensitive, shear sensitive material efficient mixing and modification of the preferred model. Suitable for: PVC cable material granulating machine, sole material, transparent bottle material, medical material, low smoke halogen-free or halogen-free flame retardant cable material, EVA shielding material, PE/EVA carbon black master batch and other cross-linked cable material, irradiation cross-linked cable material production. This set of equipment has the following advantages: excellent mixing effect and easy temperature control. Use less power and footprint. The raw material mixing and granulation process is automatic (automatic wire control), reducing personnel operation. This set of equipment does not require special operation technology, to produce high-quality products and is easy to operate. It has excellent security. Easy temperature control, thus reducing raw material damage and deterioration.

About rough material in the formula

PVC three type 75PHR- active calcium carbonate 35PHR– DOP(plasticizer) 25PHR– epoxy soybean oil 3PHR – chlorinated paraffin 20PHR- stabilizer 2.8PHR- hard acid 0.6PHR – CPE 9PHR — stone wax 1PHR

PVC cable material processing technology

The length length ratio (L/D) of SHJ-65B twin screw is 32-40;

D-150 single screw length-diameter ratio(L/D) required at 9-11;

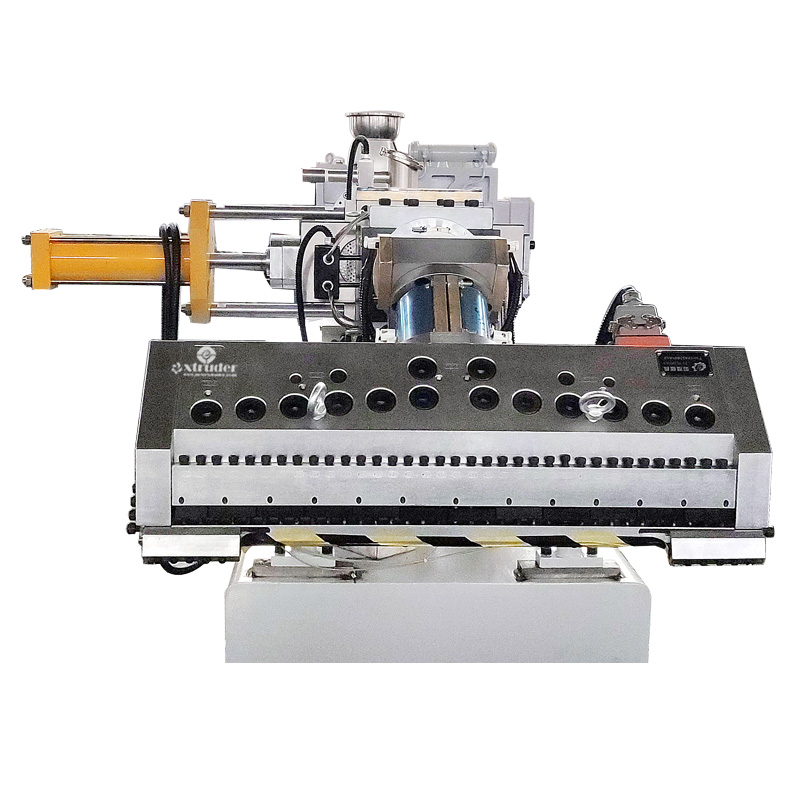

single screw axis has a water running channel in the middle; –>Hydraulic screen change –> Extrusion die-head designed by push and pull one; (Do PVC elastomer with this nose is there will be a phenomenon of clay) –>The air-cold hot-face cutting system –> The first section of the cyclone separator –>1#Vibrating sieve–>The second section of the cyclone separator –> 2#Vibrating sieve–>The third section of the cyclone separator –> extended vibrating screen –>Silo(if you need pack the bags then set an Automatic packaging machine(finish);

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |