CATEGORIES

FEATURED PRODUCTS

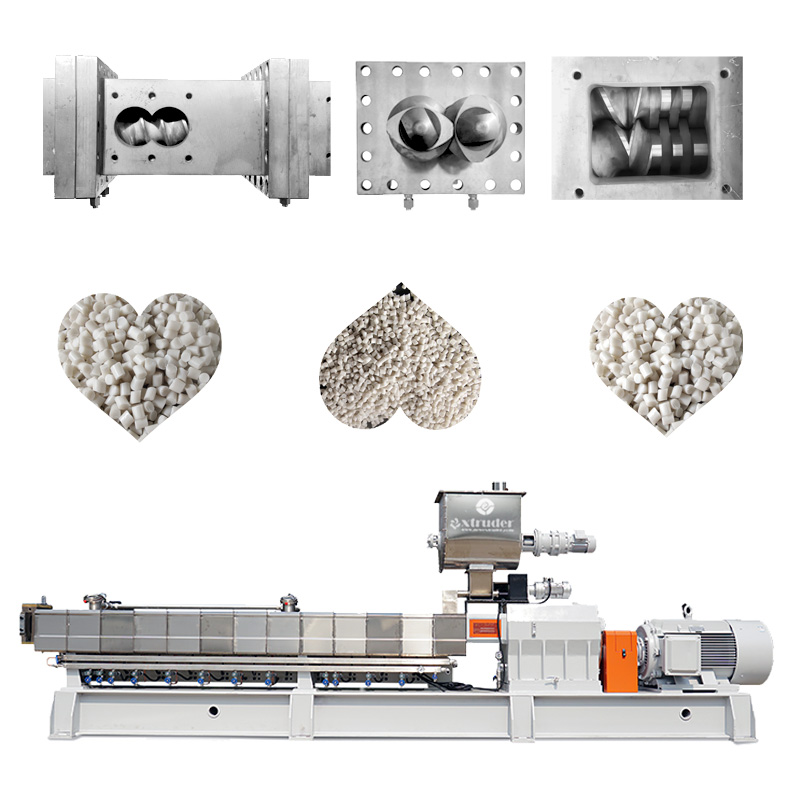

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

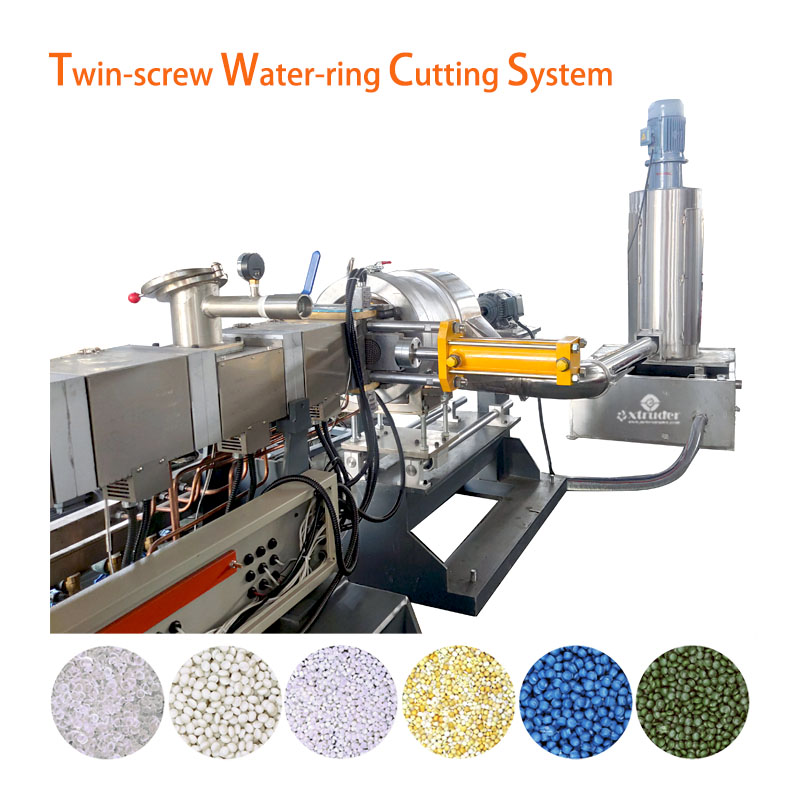

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

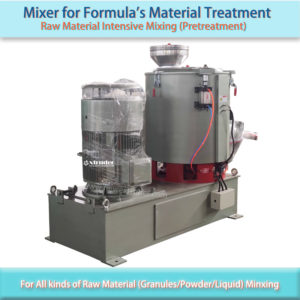

Starch powder pretreatment mixer degradable PBAT PBS PLA Corn Starch Blender Mixer

SHORT DESCRIPTION:

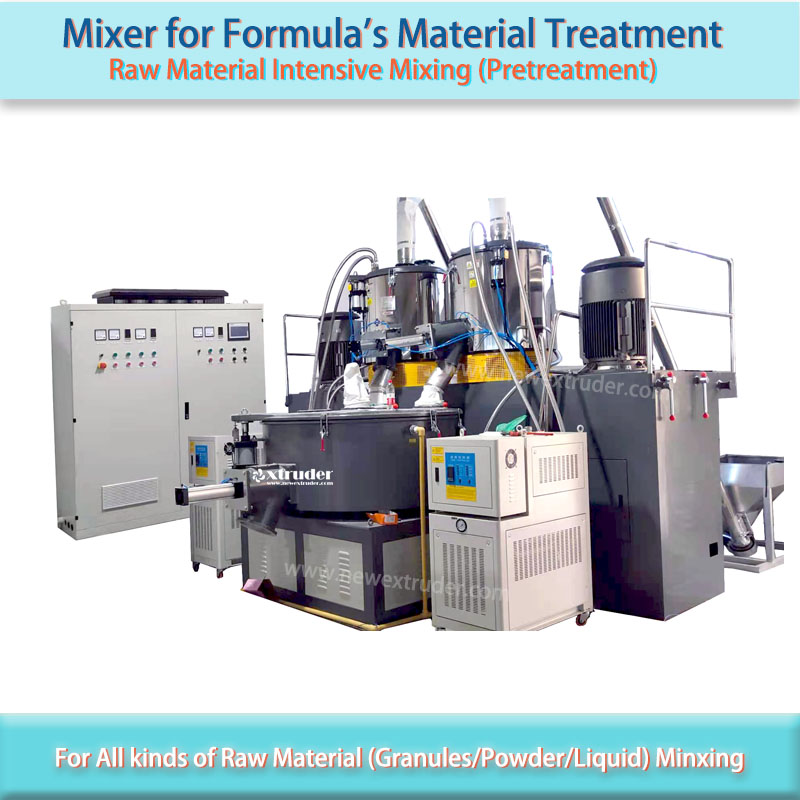

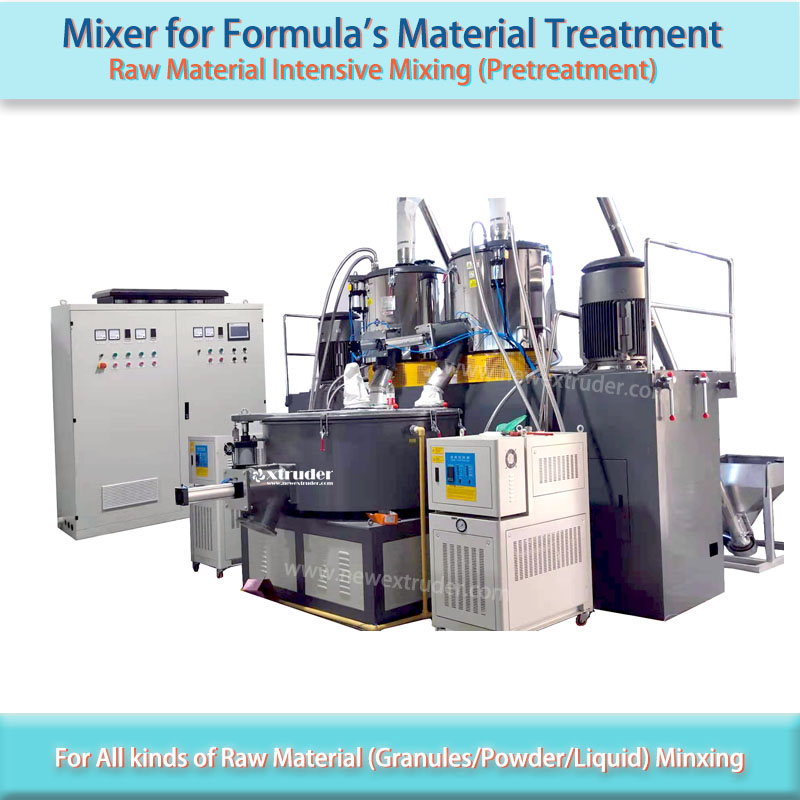

This high-speed mixer is for pre-treatment for a different kind of raw material in the formula, After full mixing and mixing evenly, the materials will be coated with each other, forming the conditions for the production of plastic-modified particles, after processing of the twin-screw mixing, shearing, compounding, and extruding into plastic strands, then it could be into plastic particles by the pelletizer cutting.

- Product Detail

- Our machine can process the following materials:

- Product Tags

Starch powder pretreatment mixer degradable PBAT PBS PLA Corn Starch Blender Mixer

HS CODE: 8479.8200.90

This high-speed mixer is for pre-treatment for a different kind of raw material in the formula, After full mixing and mixing evenly, the materials will be coated with each other, forming the conditions for the production of plastic-modified particles, after processing of the twin-screw mixing, shearing, compounding, and extruding into plastic strands, then it could be into plastic particles by the pelletizer cutting.

|

|

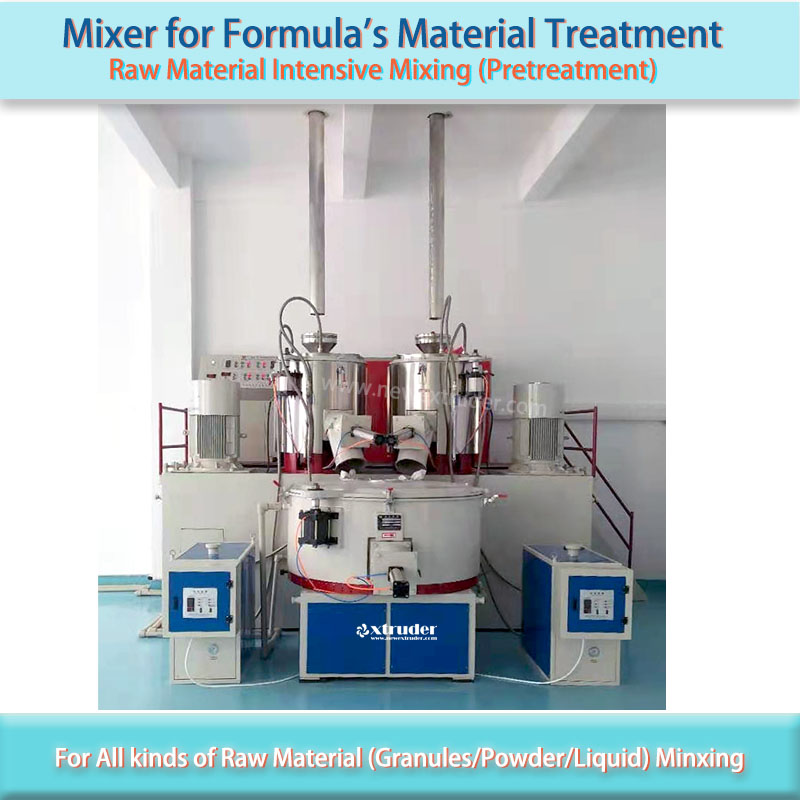

This machine group is for plastic materials mixing according to the workable formula.

The First stage is a high-speed maixer, and the second stage is low-speed mixer.

Sometimes, the materail’s temperature will be very high by self-friction after blading in the first stage: high-speed mixer, the temperature even reached into 90 centigrade or over( it’s according to how many time you mixing the raw material.)

Such high temperature raw material is difficult to feed into the extruder’s HOST, so before feeding, the material need to cooling, let the temperature goes down. This mixing group designed for such purpose and solve this problem.

High-speed mixer for Twin screw plastic extrusion lines.

|

|

Suitable for:

The user use this equipment for the formula’s different raw material mixing, let all kinds of the formula’s material mixed even, as sometimes the use will use different kinds of the raw material, like to say plastic granules, Filling powder(CaCo3/BaSO4/Talcum,Etc.), chips (WAX/Steric Acid and so on) and liquids(oil and others).

HS-CODE:8479.8200.90

|

|

This machine is for large output capacity production lines using for material mixing treatment.

Starch powder Mixer Group used in Bio degradable Plastic Granulating for Pretreatment

The machine group has 2 sets of High speed mixer plus one set of Low speed cooling Mixer for group combination.

Two stages of Mixer Group special used in Bio degradable Plastic Granulating for powders’ and other material, carriers and agents for Pretreatment mixing.

|

|

This device is for different kind of the raw material and agent in formula mixing even and thoroughly, let the different material covered each other then goes down to the next step–>feeding into the plastic extruder.

Purpose: for plastic granules raw materials mixing. Through different ingradients blading and self-friction let the materials coated each other and reached into the processing request.

Application fields: color master batch, filler, engineering granules, functional granules and other modification plastic granules making.

Use this device can mix all kinds of the raw material fully, and let them get together or wrap each other, then follow into next step: feeding them into the plastic extrusion machine line.

We can present different kind of mixer as following information:

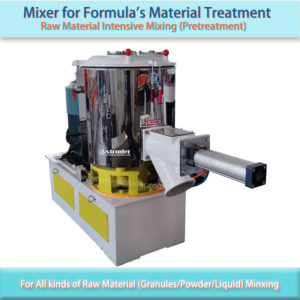

1) standard mixer for color mixing;

2) high speed mixer ( duo speed motor/ speed controlled by inverter);

3) Two stages of mixing group;(High speed mixer + cooling mixer)

4) Starch Mixer for bio-degradable plastic granules making mixing group;

5) with vertical and horizontal type;

Application & Features:

1.For plastics, rubber, daily chemical industry and laboratory materials mixing, stirring, dry blasting, painting and other craft.

2.Dual sealing has been set by the pot cover.

3.It has various of heating method: self-friction, electric heating (with or without conduction oil added) and other special heating methods.

4.Material discharge methods have two kinds: automatic temperature control or manual control.

5.Stainless steel casting blade which has refined through the static and dynamic balance test.

|

|

|

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |