CATEGORIES

FEATURED PRODUCTS

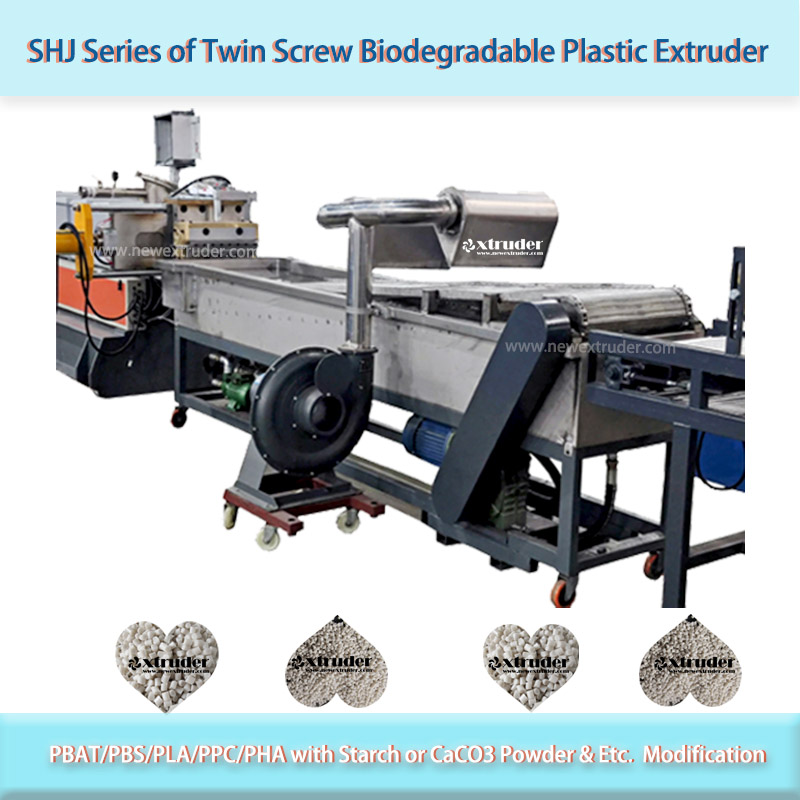

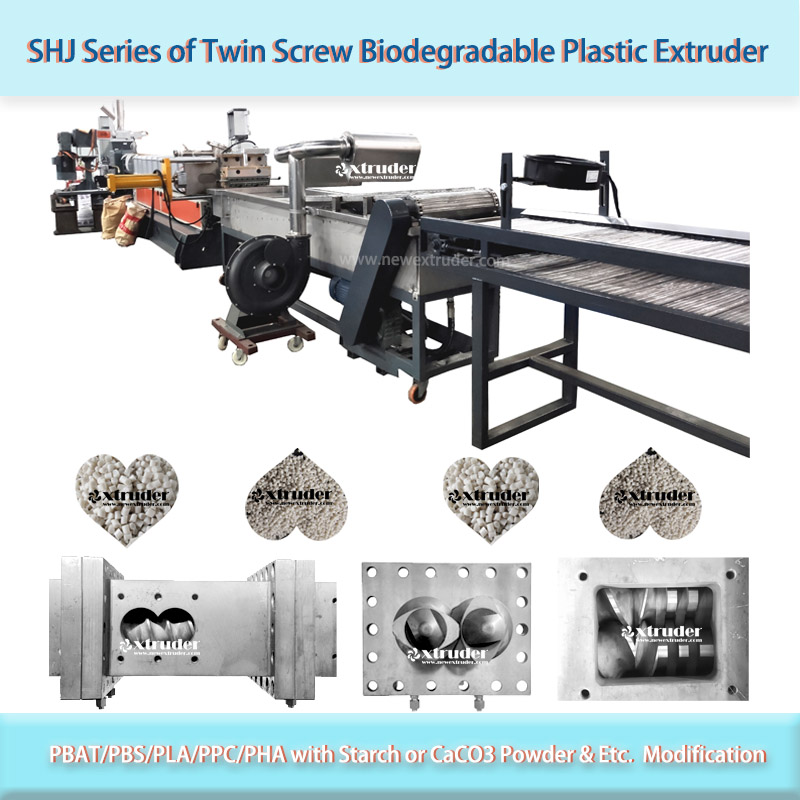

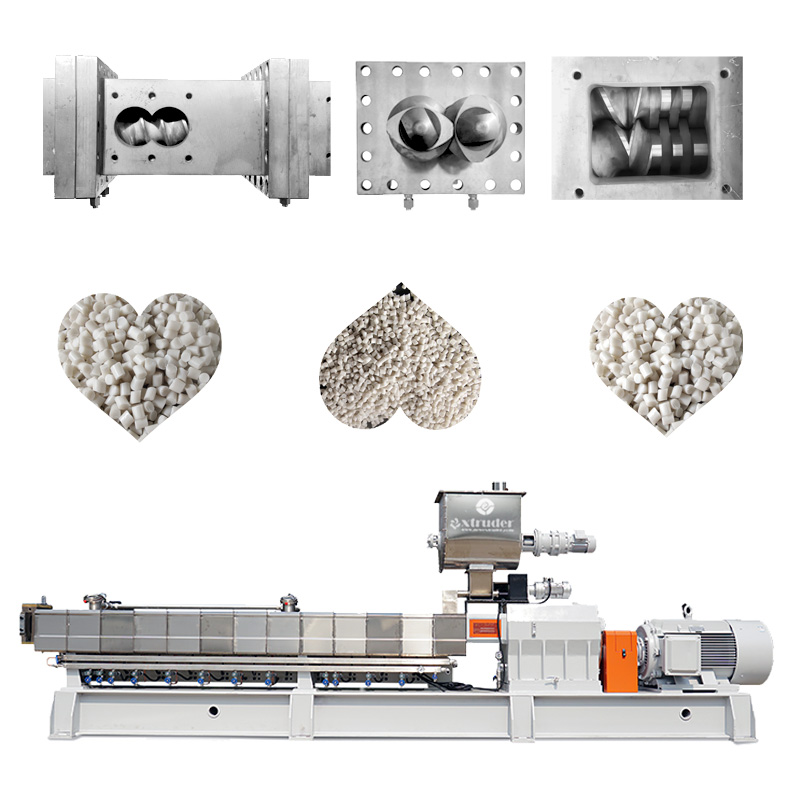

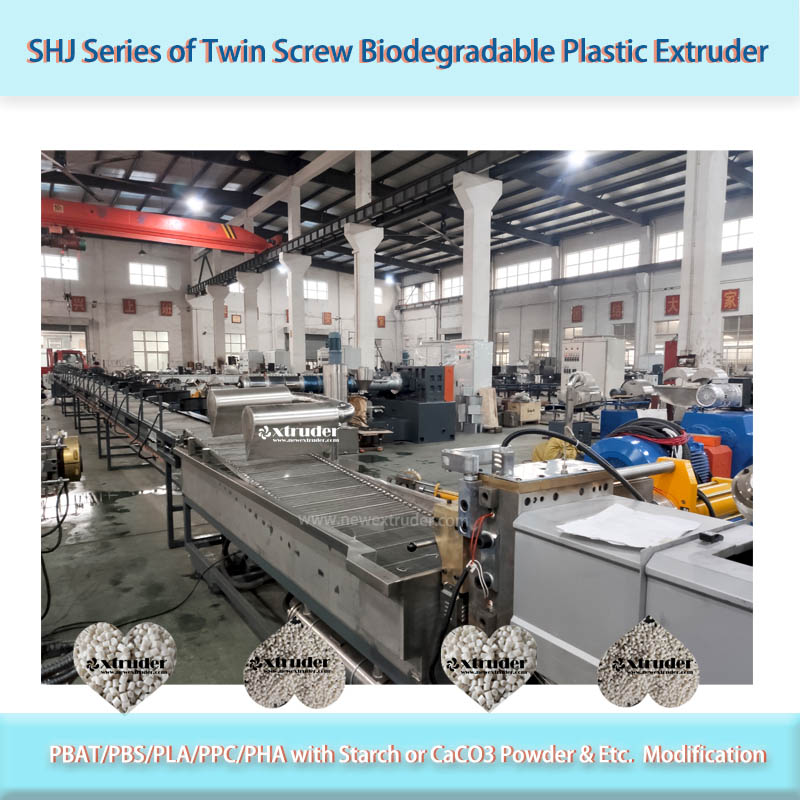

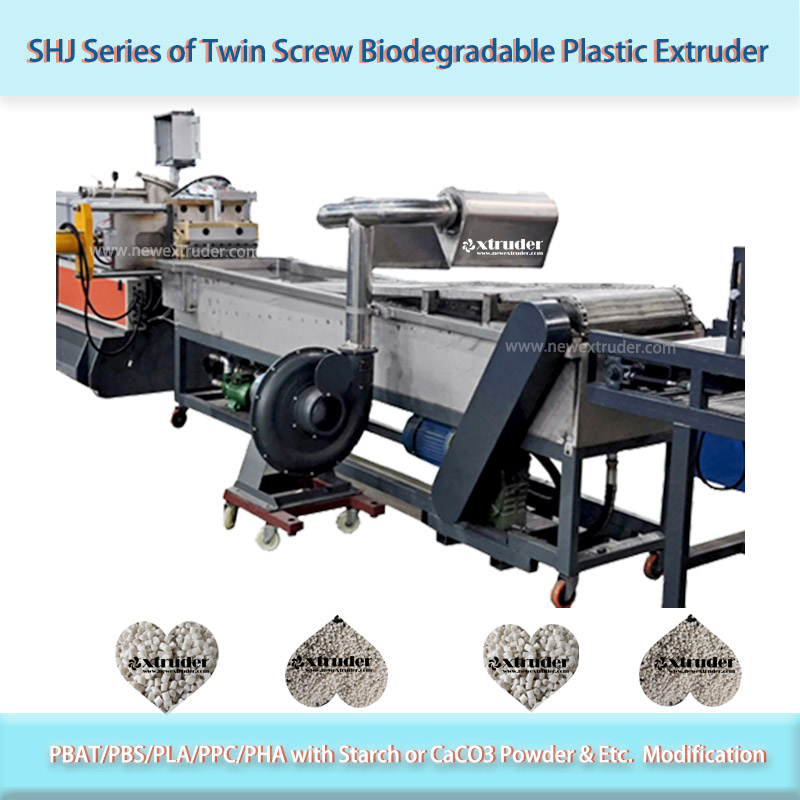

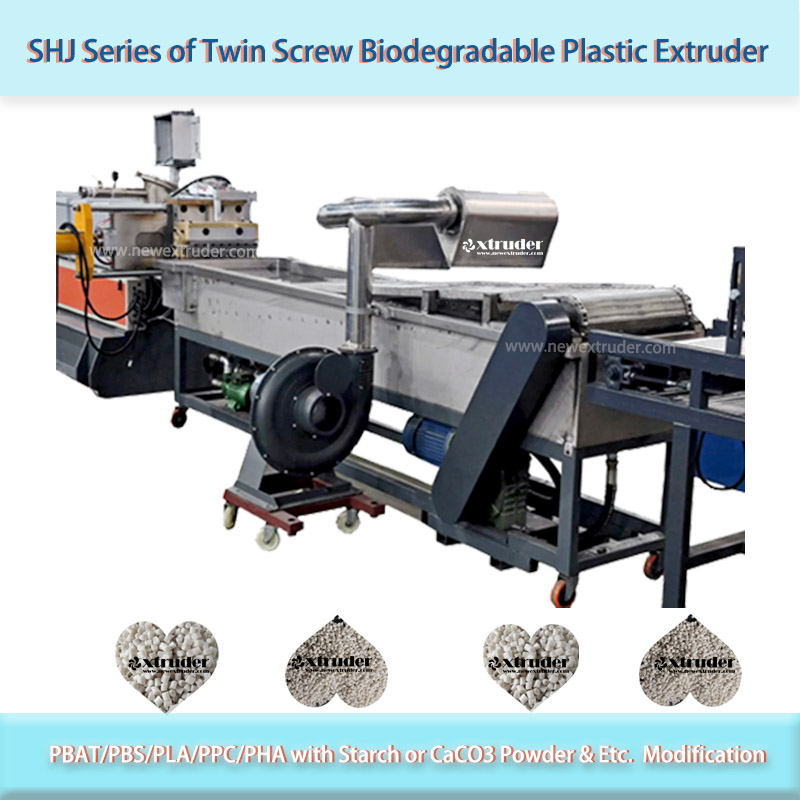

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

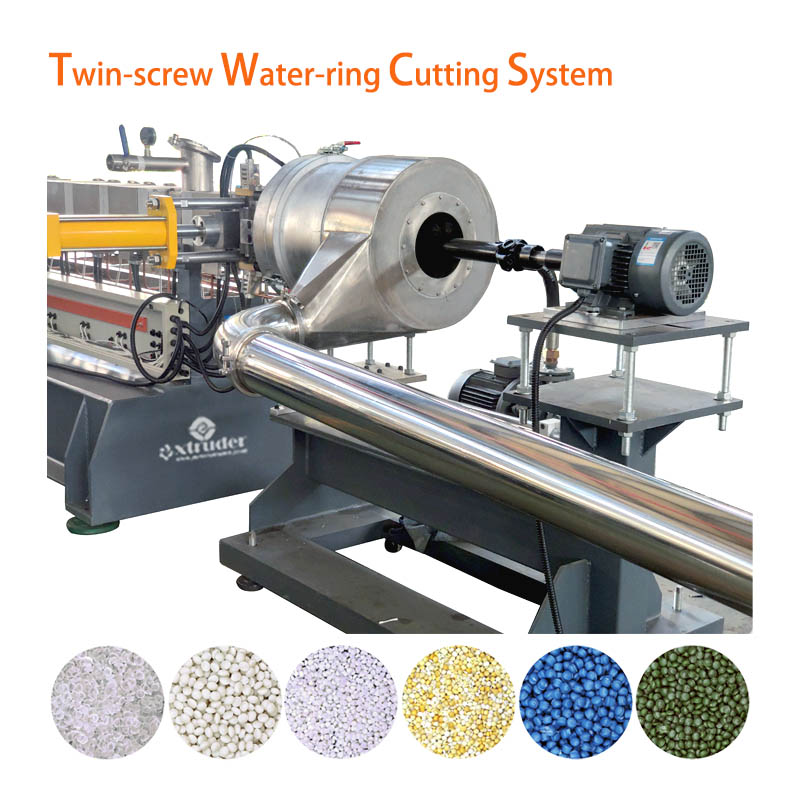

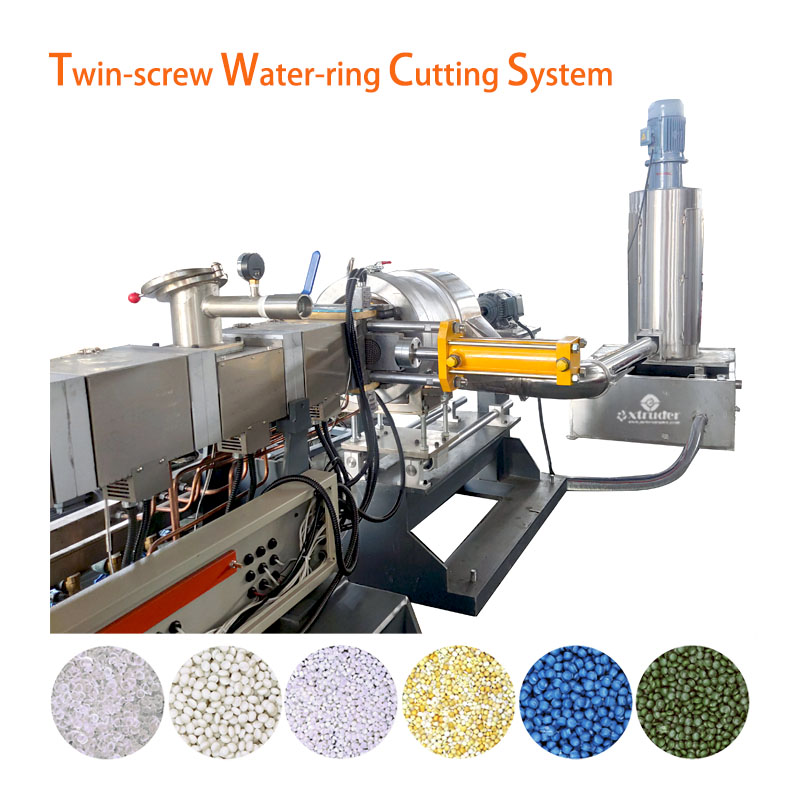

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

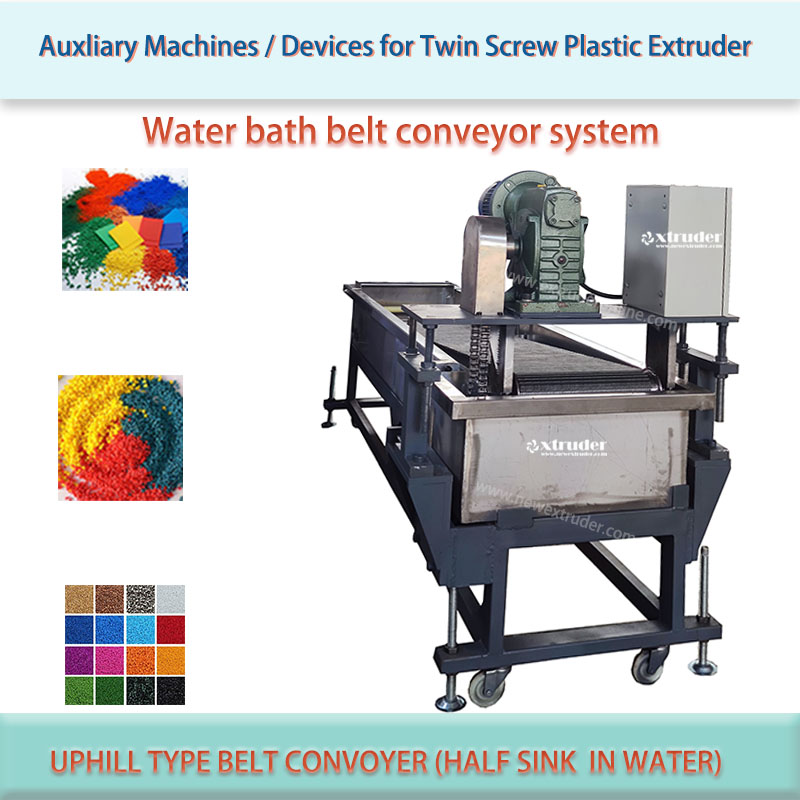

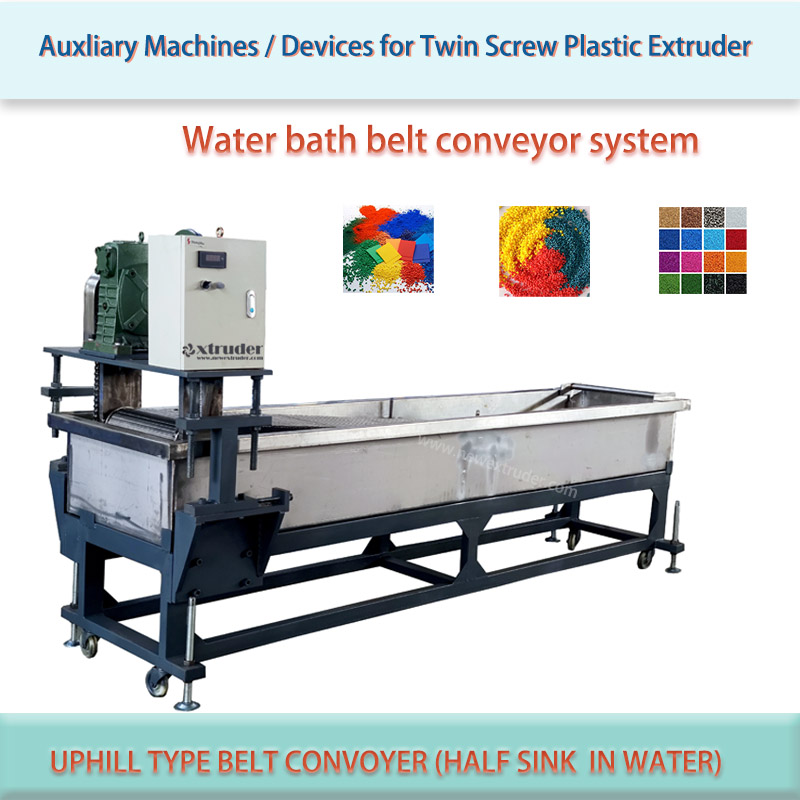

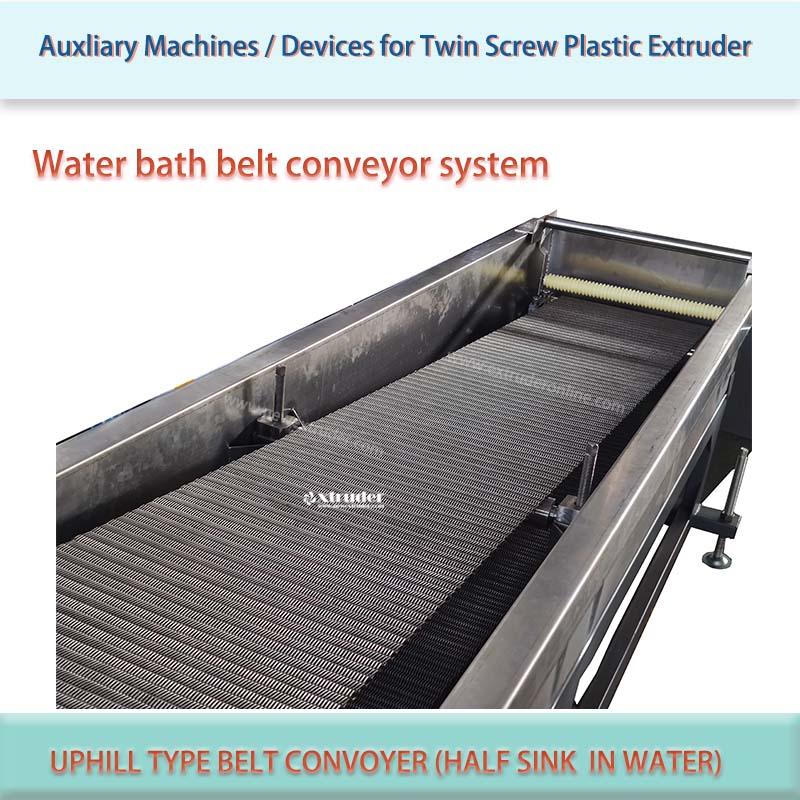

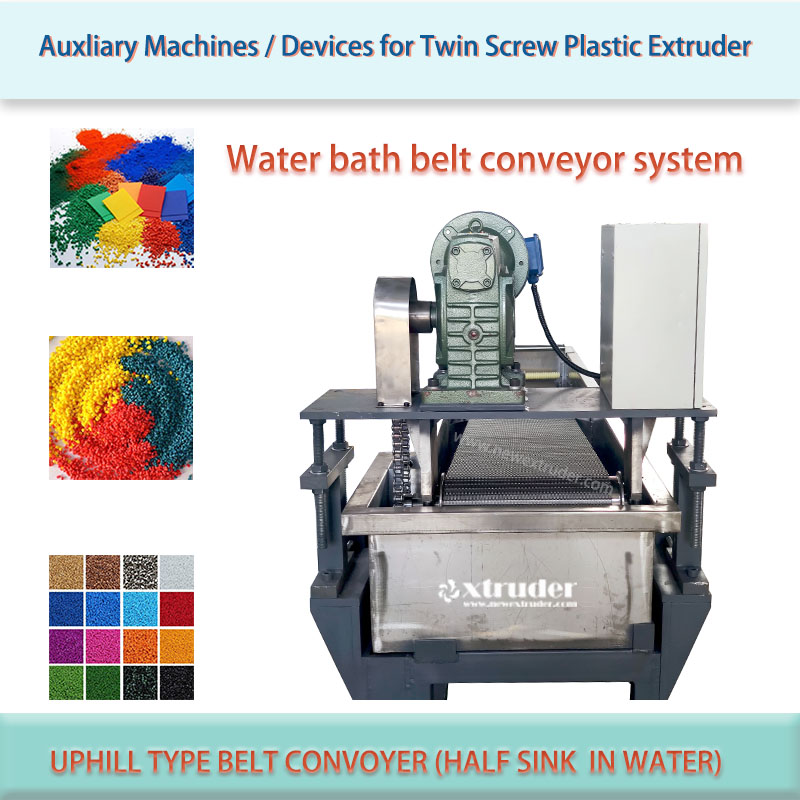

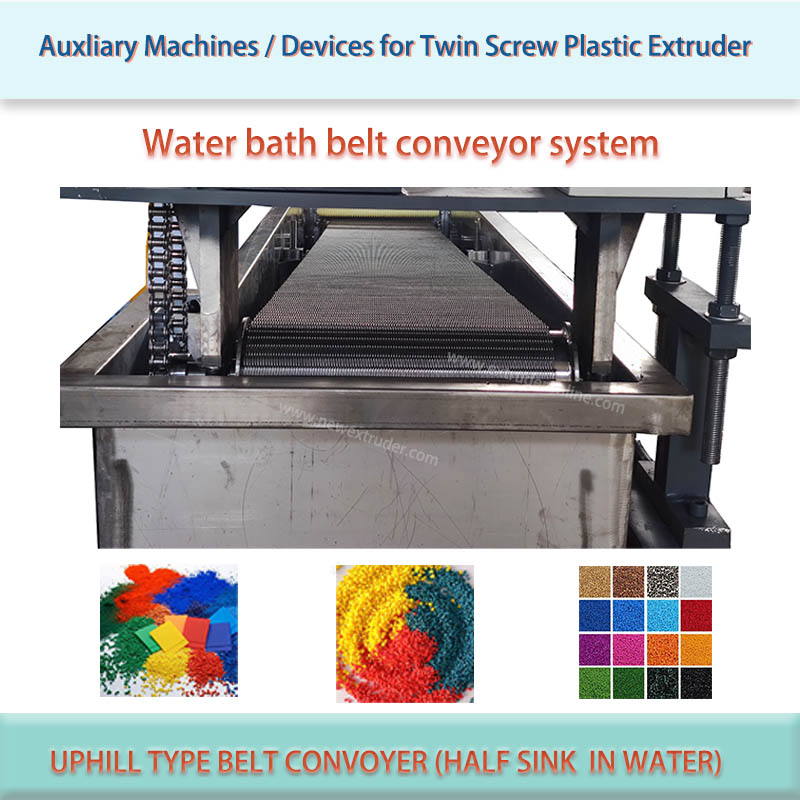

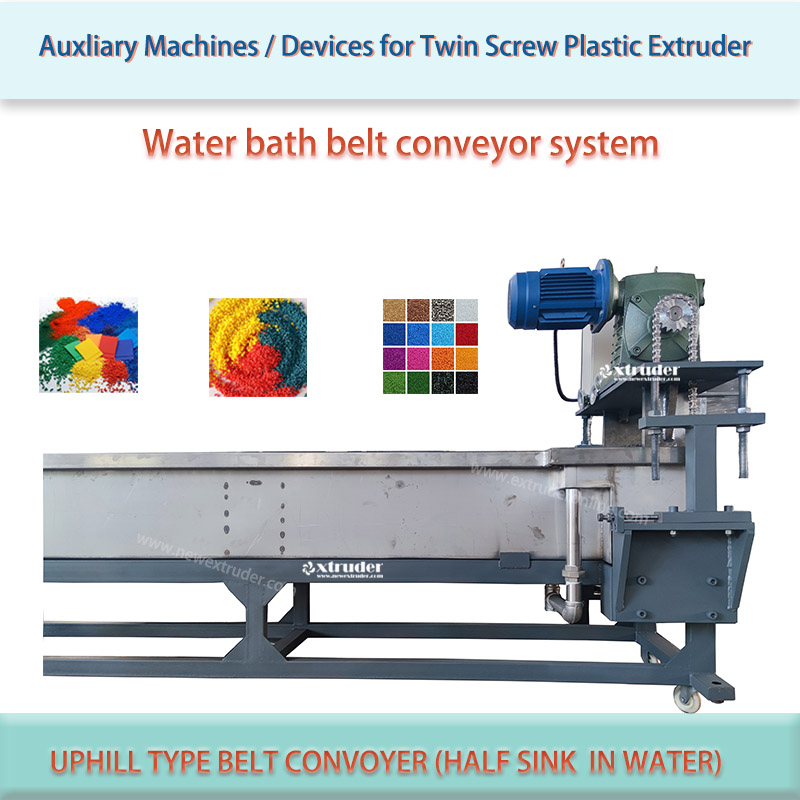

Water bath chain belt conveyor system Twin Screw Auxiliary Devices Uphill type chain belt convoyor half sink in water

SHORT DESCRIPTION:

Water bath belt conveyor system Twin Screw Auxiliary Devices Uphill type belt convoyor half sink in water This device is for strands fast cold and strands surface case-hardened then go ahead to next step: air cooling belt convoyor for strands further cold. Sometimes, it used in EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder project.

- Product Detail

- Our machine can process the following materials:

- Product Tags

Water bath belt conveyor system Twin Screw Auxiliary Devices Uphill type belt convoyor half sink in water

This device is for strands fast cold and strands surface case-hardened then go ahead to next step: air cooling belt convoyor for strands further cold.

Sometimes, it used in EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder project.

Water bath belt conveyor system for strands convoying for further step cooling.

Conveyor Belt gradeability uphill half the water (half sinking) climbing belt system

HS Code: 8477.9000

This device is for special demands, like EVA granules making, the temperature need goes down fastly, so this auxiliary machine will equipped between the end of the extrusion die head and at the beginning of the belt convoying system. This device is useful for the special technical processing request.

This device is for special demands, like EVA granules making, the temperature need goes down fastly, so this auxiliary machine will equipped between the end of the extrusion die head and at the beginning of the belt convoying system. This device is useful for the special technical processing request.

The mesh belt and water trough of the device is made by SUS 304 or SUS 201 (according to the clients’ request.)

The device equipped reducer and gearbox

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |